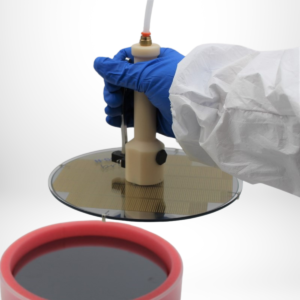

The Breeze provides state of the art touchless solutions for manually transferring wafers while introducing little to no stress to the substrate. The handling tools use compressed facility gases (typically Nitrogen or CDA - clean, dry air) to stream airflow from a center sparer cap or sparger tube to the perimeter to the wafer. Wafers are lifted from a surface, platen, cassette, or shipping container without touching the top or bottom surface of the wafer.

Following Bernoulli's principle pressure differential, the wafer is "floated" on the wand apparatus at approximately 200 microns from the surface of the Breeze plate. Coral pins limit sideways movement of retained wafer.

What is Bernoulli's Principle?

H-Square offers two standard models of Breeze handling systems - the H2B - a 90 Degree perpendicular handle apparatus, and the H2BST - a horizontal offset handle configuration.

The Breeze provides state of the art touchless solutions for manually transferring wafers while introducing little to no stress to the substrate. The handling tools use compressed facility gases (typically Nitrogen or CDA - clean, dry air) to stream airflow from a center sparer cap or sparger tube to the perimeter to the wafer. Wafers are lifted from a surface, platen, cassette, or shipping container without touching the top or bottom surface of the wafer.

Following Bernoulli's principle pressure differential, the wafer is "floated" on the wand apparatus at approximately 200 microns from the surface of the Breeze plate. Coral pins limit sideways movement of retained wafer.

What is Bernoulli's Principle?

H-Square offers two standard models of Breeze handling systems - the H2B - a 90 Degree perpendicular handle apparatus, and the H2BST - a horizontal offset handle configuration.

Showing all 14 results